The terms ‘conventional’ and ‘unconventional’ gas are often misunderstood and have taken on different meanings in different reports relating to the gas industry.g

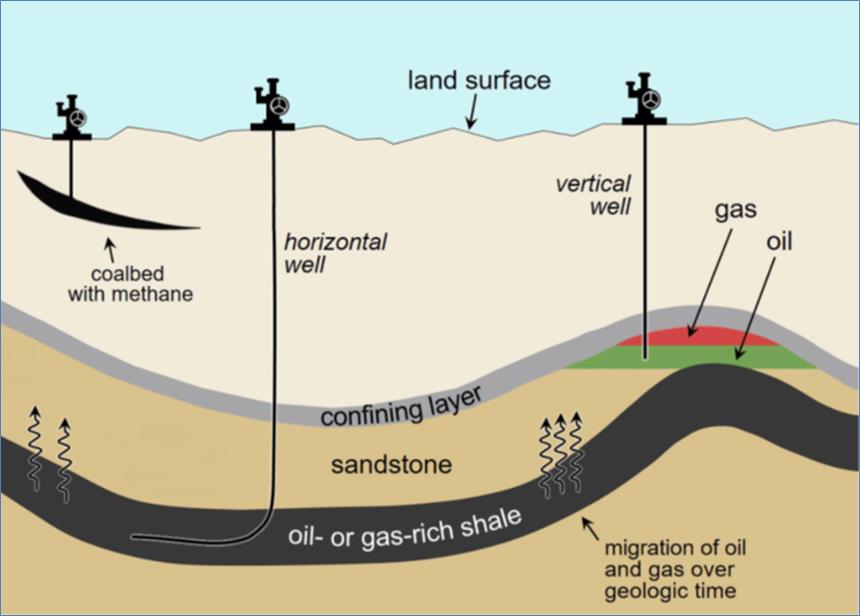

For the purpose of this Inquiry, ‘unconventional’ gas is found in source rocks such as coal and shale where the gas has been trapped in place (see the “oil-or gas-rich shale” in Figure 1). This is different from ‘conventional’ gas, which migrates into porous, permeable rocks and is trapped under a seal.

Conventional gas can typically be developed with a limited number of wells due to the accumulation of the hydrocarbons in a confined area with well-connected pore spaces within the source rock enabling effective drainage from strategically placed wells. The gas will flow to the surface under its own pressure driven by a water table (or aquifer) underneath an expanding pressurised gas cap overlying the gas (see the oil and gas accumulation below the “confining layer” under “vertical well” in Figure 1).

By contrast, with unconventional gas, the source rocks that hold the gas have much lower porosity (that is, the void spaces between the grains that make up the rock are very small) and much lower permeability (that is, the interconnectedness of the pore spaces to allow the gas to move through the rock is very low). Therefore, in order to make the gas flow, artificial stimulation, such as hydraulic fracturing, must be used.

Improvements have been made to the production of conventional gas and many of these techniques have been refined and applied to unconventional gas. Horizontal drilling and hydraulic fracturing have been used for decades on conventional reservoirs but better efficiency and accuracy has allowed this technology to be used in unconventional gas reservoirs making them economically viable.

Figure 1: Schematic showing different types of petroleum

accumulations and development.

Source:

Modified from U.S. Environmental Protection Agency.

There are misconceptions surrounding the differences between coal seam gas and shale gas. There are significant distinctions between the development of gas from coal seams and the gas from deep shales.

It is important to know what these differences are because this Inquiry is only concerned with onshore unconventional deposits of shale.

The main differences are indicated in Table 1 below. These include the fact that:

Coal seam gas | Shale gas | |

|---|---|---|

Source | Shallow coal seams | Deeper shales |

Depth | 300 m – 1,000 m | 1,500 m – 4,000 m |

Drilling direction | Mainly vertical | Horizontal and vertical |

Proximity to aquifers | Shallow and therefore closer to potable water resources | Deeper and therefore further away from potable water sources |

Surface footprint | Single exploration well per drill pad (a drill pad is the area disturbed by the installation of the drilling and extraction equipment) meaning a larger number of well heads in a given area. | Multiple wells can be drilled from each well pad meaning a lower number of completed well heads in a given area than for coal seam gas. |

Hydraulic fracturing | Hydraulic fracturing in some coal seams with low permeability | Always requires hydraulic fracturing |

Hydraulic fracturing extent (length x height) | 200 – 300 m x 5 – 30 m | 200 – 6,000 m x 30 – 300 m |

Hydraulic fracturing pressure | 35 MPa or 5,000 psi | 35 – 70 MPa or 5,000 –10,000 psi |

Water use | Requires dewatering of coal | No dewatering, but water is used for drilling and hydraulic fracturing |

Hydraulic fracturing fluid volume per well | Approximately 1 ML (0.1 – 3 ML) | Approximately 20 ML (5 – 40 ML) |

Number of wells required | Larger number of wells | Fewer wells required than for coal seam gas |

Productivity (over lifetime of well) | Lower gas recovery (0.5 – 2PJ per well) | Higher gas recovery (2 - >10PJ per well) |

Table 1: Typical differences between coal seam gas and shale gas. The data given in the above table will vary from case to case. Sources: CSIRO, Northern Territory Government.

Shale gas is mainly methane that is trapped within clay-rich sedimentary rock at depths greater than 1,500 metres. The low permeability of the rock means that gas, either absorbed or in a free state, in the pores of the rock, is unable to flow easily.

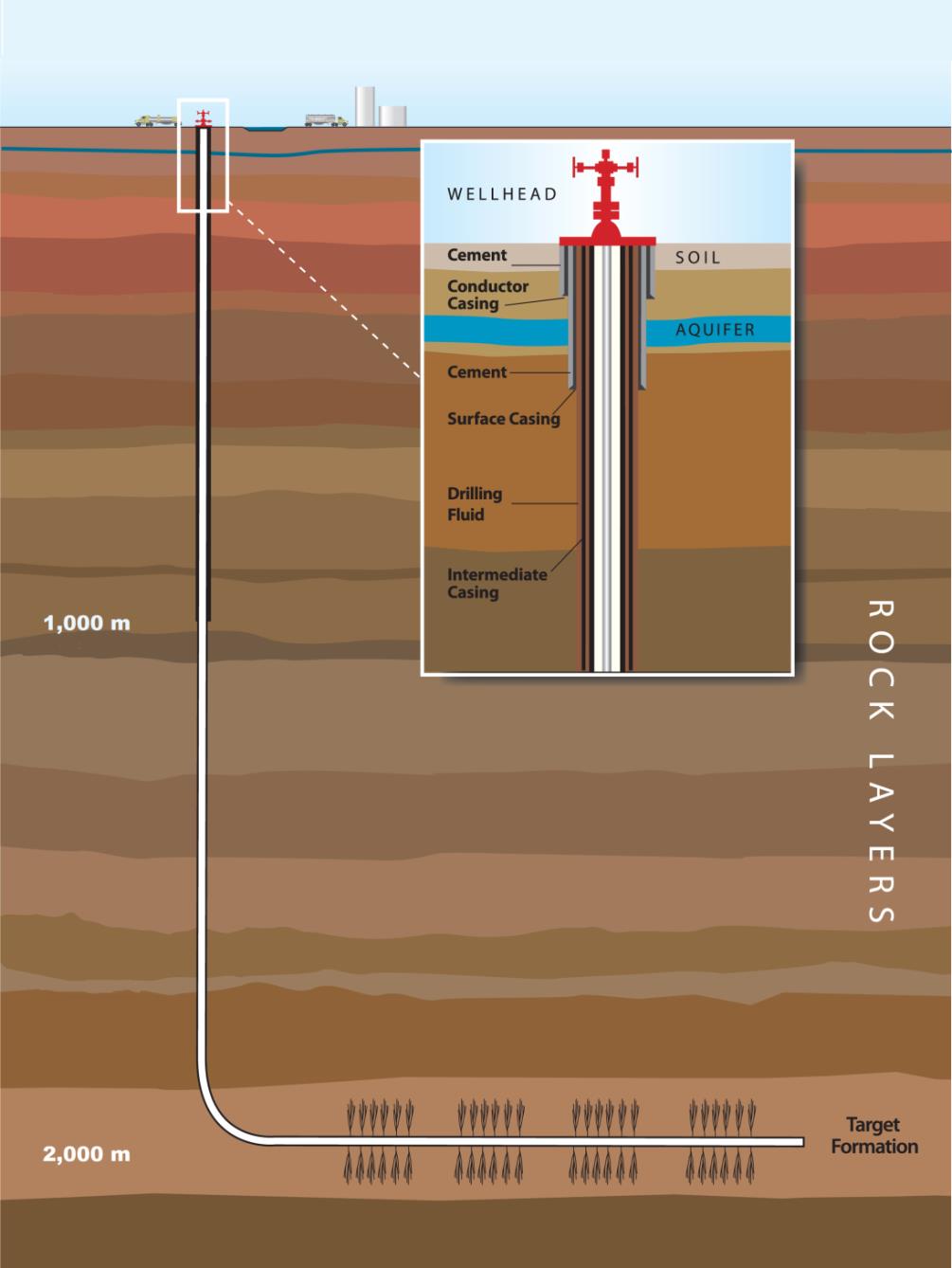

To extract shale gas, wells are drilled anywhere from 1,500 – 4,000 metres deep through various layers of rock to access the shale. The wells are lined with various steel casings as shown in Figure 2 below, which are cemented using fit-for-purpose cement designed to protect groundwater from contamination.

To maximise shale gas recovery a technique called horizontal drilling is used. This technique typically involves the well changing from a vertical to a horizontal direction deep underground, away from any aquifer.

Figure 2: Schematic diagram showing typical well construction, casing, and horizontal drilling. Source: Modified from Society of Manufacturing Engineers.

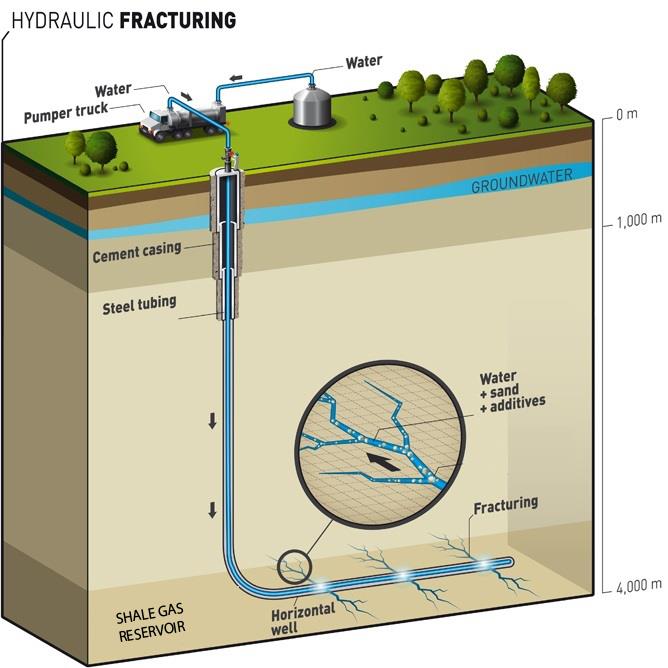

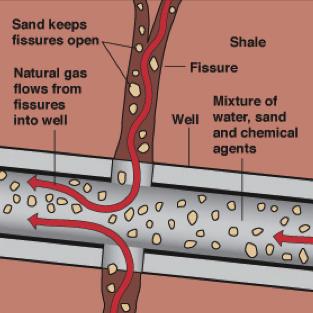

Before gas can be extracted from the shale gas reservoir, hydraulic fracturing must occur. Hydraulic fracturing is a technique used to enhance the production of the gas. Hydraulic fracturing refers to the injection of fluid (comprising approximately 99.5% water and proppant (sand) and approximately 0.5% chemical additives) at high pressure into targeted sections of the layers of gas-bearing rocks. This creates localised networks of fractures that unlock gas and allow it to flow into the well and up to the surface.

Figure 3: Schematic diagram of shale gas extraction process. Source: Modified from Total S.A.

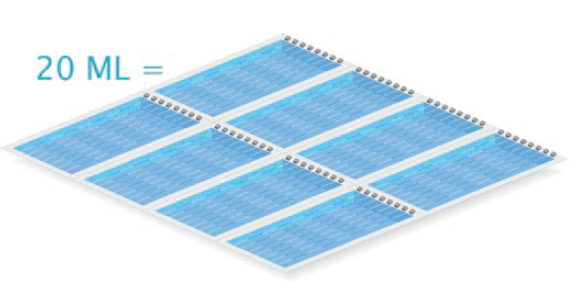

An average of about 20 to 30 megalitres (ML) of water is used per fracked horizontal well, which would fill approximately between 6 – 10 Olympic sized swimming pools.

Figure 4: 20 megalitres would fill approximately 8 Olympic sized swimming pools. Source: CSIRO Gas Industry Social and Environmental Research Alliance..

To prevent the fractures in the rock from closing, proppant is added to the fracturing fluid and remains in the fractures holding them open as shown in Figures 3 and 5.

Figure 5: Diagram of proppant in action. Source: Modified from Al Granberg.

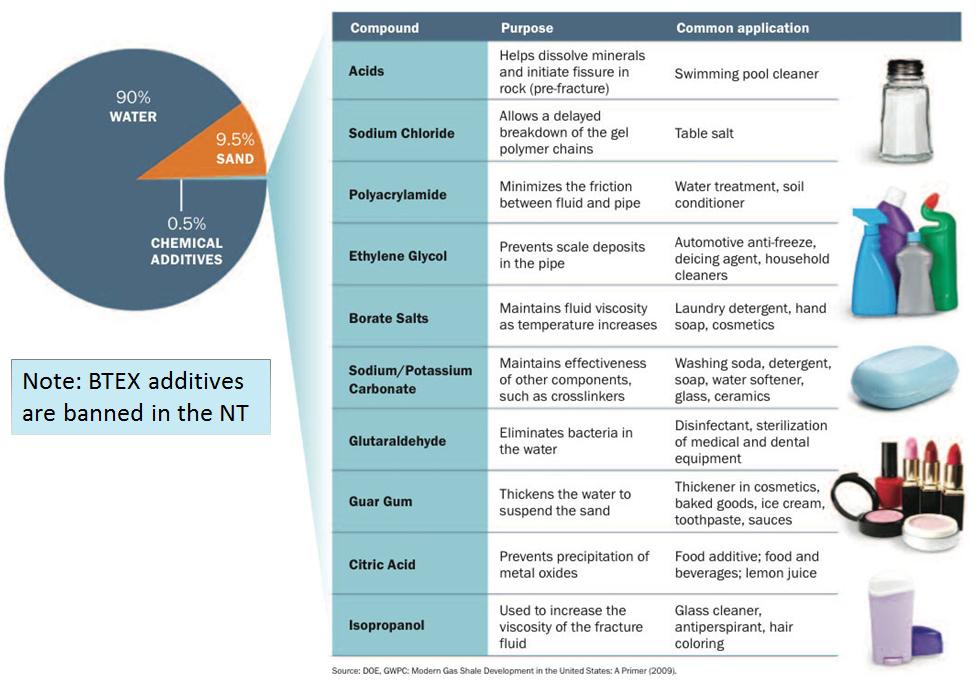

Water and proppant make up around 99.5% of the hydraulic fracturing fluid. Added chemicals make up the other 0.5%. The following chemicals are commonly added to the water to perform the following functions (see Figure 6 below):

a gelling agent, such as guar gum, is used to create a gel to suspend the proppant in the water and transport the proppant through the fracture;

a gel breaker, such as ammonium persulfate (used in hair bleach), that reduces the viscosity or thickness of the hydraulic fracturing gels so that they can transmit water, and gas surfactants, such as ethanol, together with a cleaning agent, in order to allow high pump rates and reduce pressure;

a bactericide or disinfectant, such as sodium hypochlorite (pool chlorine) and sodium hydroxide (used to make soap), to control bacteria growth in the well that contaminates the gas and restricts gas flow; and

acids and alkalis, such as acetic acid (vinegar) and sodium carbonate (washing soda), to assist in the initiation of the fracture and improve fluid flow in the rocks.

Toxic BTEX chemical additives (benzene, toluene, ethylbenzene and xylenes) are banned in the Northern Territory for use in the extraction of unconventional gas.

Figure 6: Typical hydraulic fracturing fluid additives that may be used. Source: Modified from US Department of Energy, 2009, Modern Shale Gas Development in the United States: A Primer.

Video courtesy of CSIRO

Video courtesy of CSIRO